IDRAK Technology Transfer MMC həm avtomobil yollarında, həm də dəmir yollarında hərəkət edə bilən unikal, pilotsuz nəqliyyat vasitəsi layihələndirmişdir.

Ətraflı

Biometrik kiosk istifadəçinin fərdi məlumatlarının və biometrik xüsusiyyətlərinin müstəqil qeydiyyatı üçün nəzərdə tutulmuşdur. Kiosk informasiya təhlükəsizliyi və məxfiliyin bütün tələblərinə riayət etməklə özünəxidmət rejimində identifikasiya məlumatlarının toplanması və qeydiyyatını təmin edir.

Ətraflı

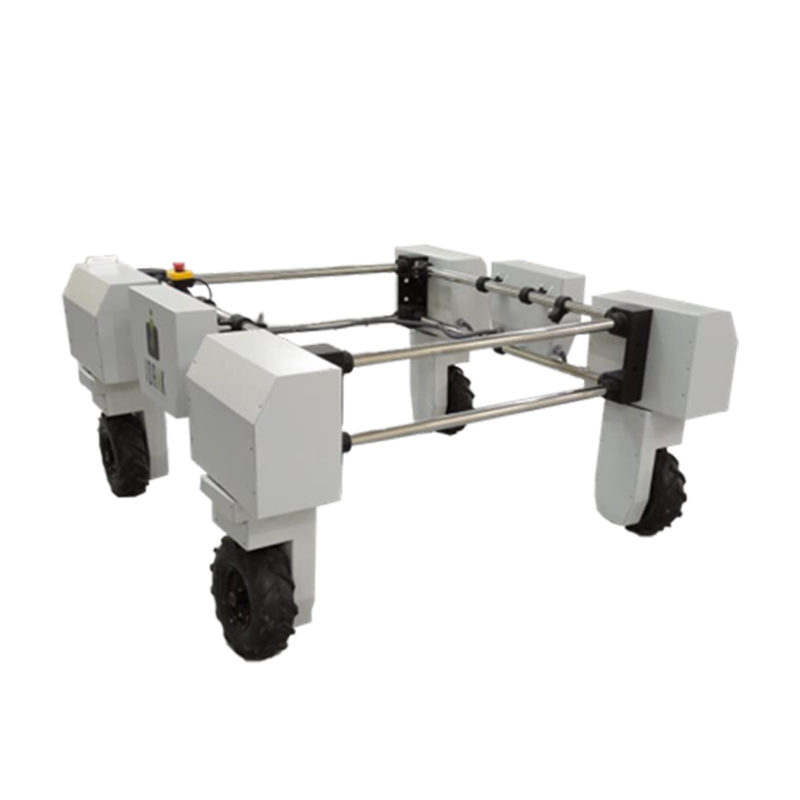

Aqro-robotlar – bitki toxumları yerləşdiriləcək çuxurların avtomatik qazılmasını, əkinlərin böyüməsi əsnasında doğru miqdarda qida, gübrə verilməsi, böcək dərmanlarının avtomatik şəkildə tarlalara səpilməsi, bitkilərin mühafizəsini, suvarmanı və s. işləri yerinə yetirir.

Ətraflı